We have always believed that fine watchmaking should open itself up to the world and to a broad spectrum of disciplines. A watch should be both sophisticated and practical, easy to use, and comfortable on the wrist.

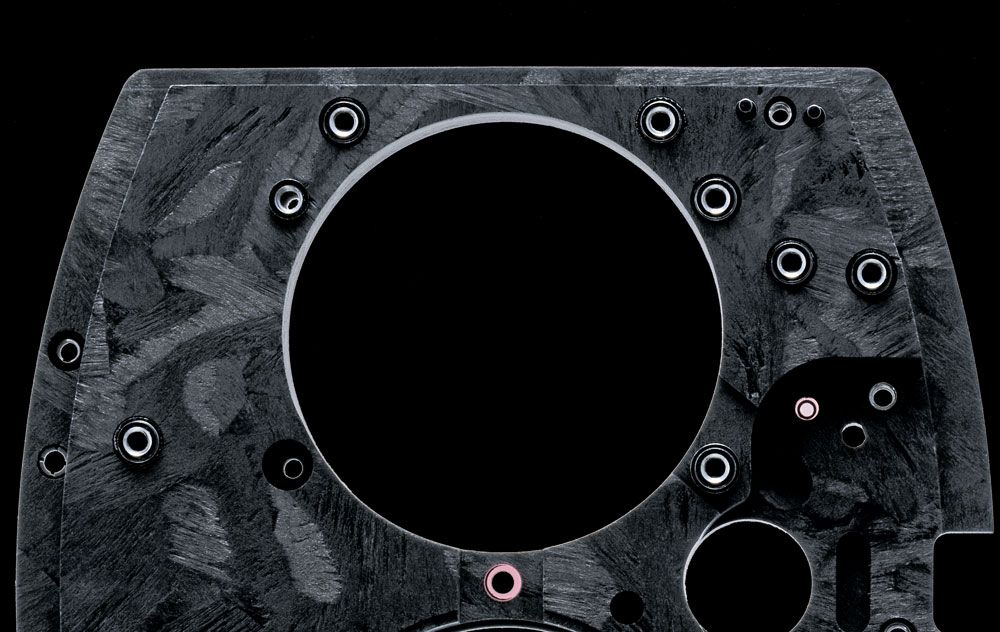

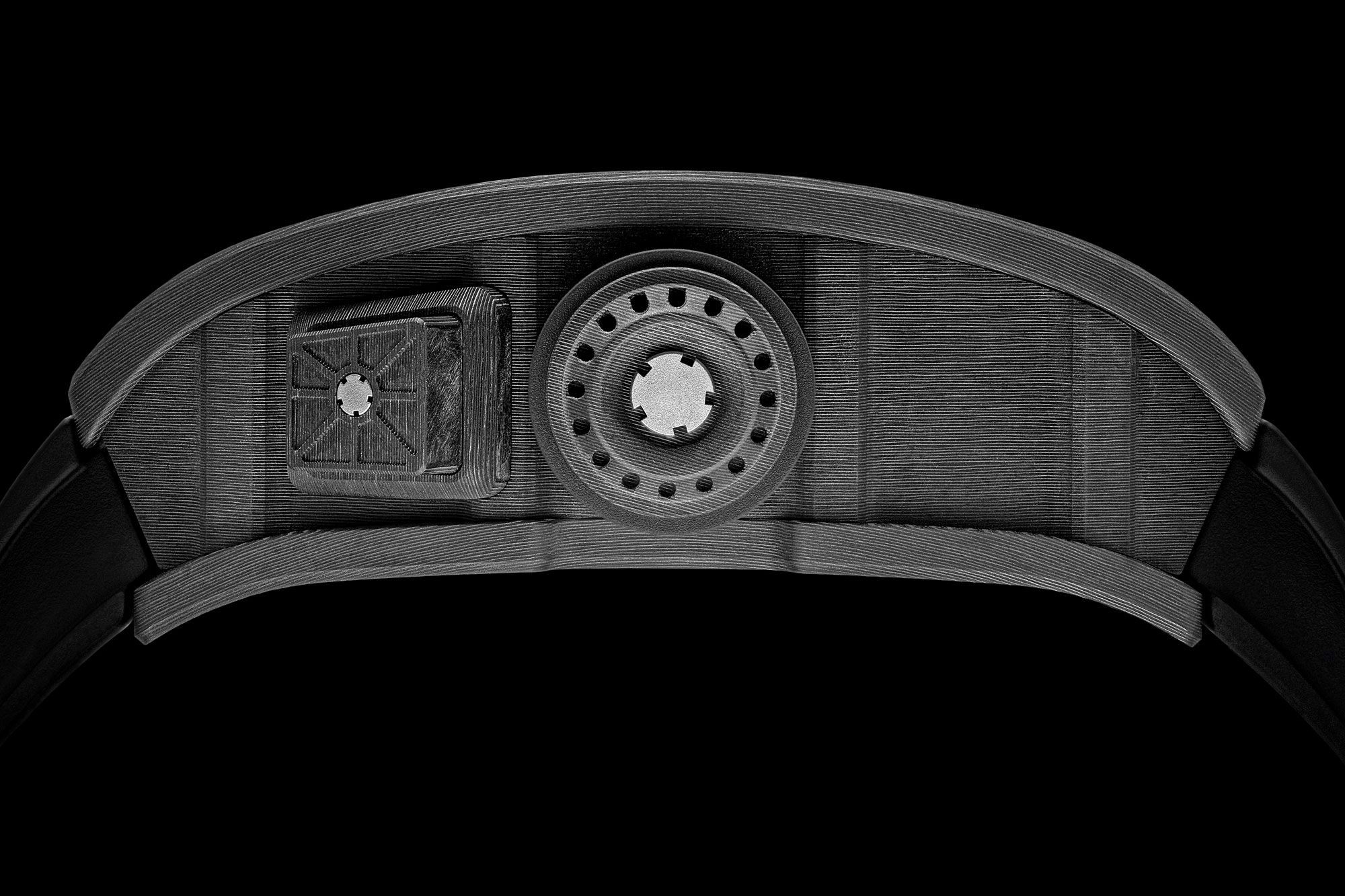

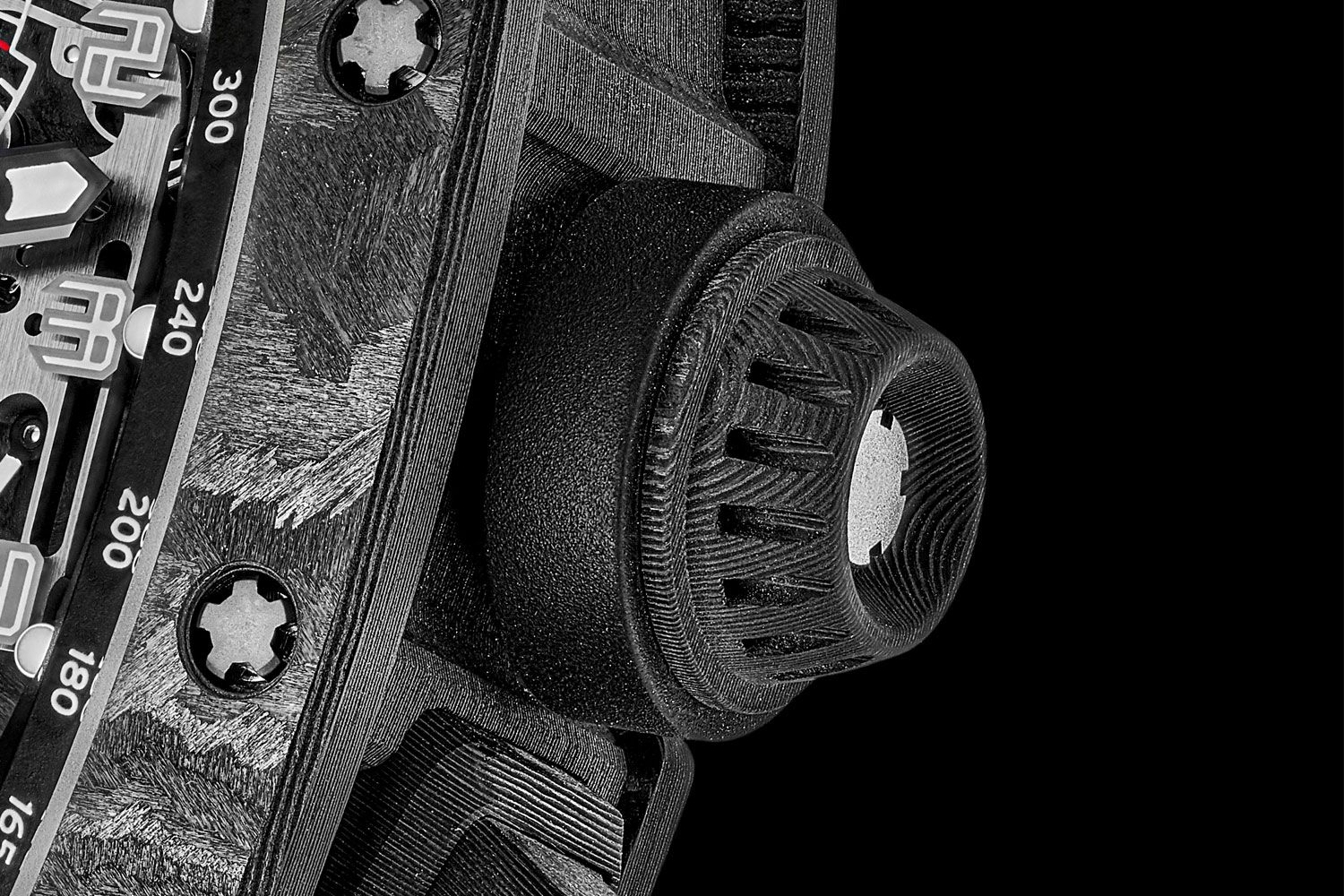

With the introduction of the RM 004 in 2004, after more than five years of development to perfect it, Richard Mille launched a new generation of split-seconds chronograph watches. For example, research was conducted into the geometric design of the column wheels that control the different levers, in order to ensure the perfect, long-term, stable and simultaneous functioning of the chronograph mechanism, a feature essential to any high-performance chronograph.

This column-wheel chronograph boasts an improved split-seconds mechanism that virtually eliminates the unpredictable jumping of the second seconds hand afflicting many split-seconds chronographs.